NON-TOXIC, CYANIDE-FREE TECHNOLOGY CAN POTENTIALLY DOUBLE SILVER RECOVERIES AND SIGNIFICANTLY CUT LEACHING TIMES

VANCOUVER, BC, April 2, 2024 /CNW/ — Silver One Resources Inc. (TSXV: SVE) (OTCQX: SLVRF); (FSE: BRK1) – “Silver One” or the “Company”) announces the results of initial metallurgical testing using a novel, cyanide-free leaching process that can potentially double silver recoveries and cut leaching times. The leaching process is used in conjunction with a unique extraction process which is suitable for the recovery of silver from refractory mineralization. This innovative leaching process involves a trademarked technology called TNS, developed by Extrakt Processing Solutions, LLC (“EPS”) Ky, USA. The tests were conducted on representative samples of the largest heap leach pad (LP1) from the Company’s 100% owned, past-producing Candelaria Silver Mine in Nevada. Recently, EPS announced a strategic global alliance with Bechtel Energy Technologies & Solutions, Inc. (“Bechtel”) to commercialize Extrakt’s groundbreaking TNS™ technology (see https://www.bechtel.com/newsroom/press-releases/extrakt-and-bechtel-partner-to-commercialize-groundbreaking-solid-liquid-separation-technology/).

Highlights

-

Preliminary metallurgical testing using EPS’ proprietary solutions have significantly increased Candelaria’s leach pad silver recoveries, exceeding 100% in comparison to previous testing using cyanide leaching (see Company’s news release of May 21, 2019).

-

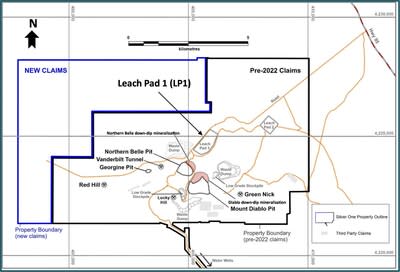

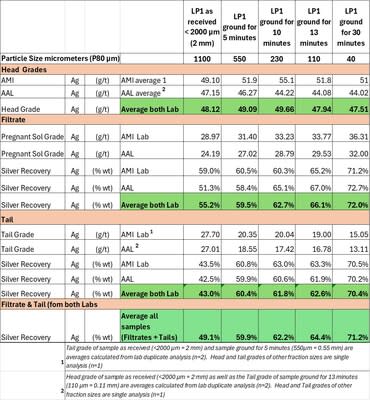

The sample tested consists of leached oxides from LP1, crushed to <1 inch (<25.4 mm) by previous operators, and has an average silver grade of 48.1 g/t. Crushing the leach pad material to ≤2 mm (2000 microns) has returned an average silver recovery of 49% in comparison to the cyanide leach test recoveries of 21% to 29% from past tests commissioned by the Company (see Company’s news releases of April 19, 2018 and May 21, 2019, and figure 1 for the location of LP1).

-

Additional short-term (5-15 minutes) milling to 550 and 110 microns (0.55 and 0.11 mm) increases the leach pad recoveries to 59.9% and 64.4%, respectively.

-

The use of the trademarked TNS technology has positive ESG implications, notably because it reduces environmental impact. Unlike cyanide use, this process consumes minimal water, and no toxic effluents are produced. Furthermore, the residues (tailings) are inert and non-acid generating.

-

Additional testing on material from both the existing leach pads and fresh ore is planned for the second half of 2024.

Gregory Crowe, President and CEO commented: “The impressive results from the initial testing using EPS’ technology have encouraged Silver One to expand this testing to cover both leach pads and fresh mineralization. The results show the technology performs well in the treatment of difficult or refractory mineralized material, such as the partially leached material on the Candelaria heap leach pads. The use of these proprietary solutions yields potential for possibly doubling silver recoveries in comparison to traditional cyanide leaching. This may positively impact the overall economics of the project. EPS’ leaching agents not only improve silver extraction but are also more environmentally friendly and save water by assisting in the dewatering of tailings, and the extraction process is simpler and potentially less costly. Furthermore, we are optimistic about this innovative technology as it is backed up by EPS’ years of research and development. We are looking forward to continuing testing to optimize the operating parameters, test diverse types of mineralized material including fresh never-leached material, and validate the results.”

Background

EPS has developed a novel solid-liquids separation technology (TNS™) and leach processes to recover metals. EPS extensive research and development has resulted in constant improvements and adaptations that have accumulated 40 patents, producing, in the process, formulations suitable to separate metals from complex oxide and refractory mineralized materials. TNS™ technology was designed for the application of liquid solids separation in dewatering of mine waste and is also very effective in separating hydrocarbons in oil-sands. The TNS™ process, combined with its unique cyanide-free leach technology especially formulated to extract metals, has demonstrated to recover more silver and gold than traditional leaching methods.

The traditional silver cyanide leaching typically takes several hours to several days using agitated leaching techniques. However, EPS’ innovative technology uses patented chemistry to extract metals in less time than an agitated leaching system. It also separates liquids from solids, enabling dry-stacked tailings; it works with coarse particles (≤2 mm or 2000 microns material in Candelaria’ s case) and is not inhibited by the presence of clays. Thus, the process potentially reduces capital and operating costs while increasing metal recovery.

The TNS technology has been tested on materials from mine sites from various parts of the world and piloted successfully in dewatering oil-sand tailings in Canada and with major coal operation in the U.S. The leach technology is also in the process of being tested in the extraction of gold from tailings for a project in Canada.

Testing and Leach Results

A bulk sample representative of leach pad 1 (LP1) weighing 228 kg and entirely crushed to ≤2 mm (<2000 microns) with a Vertical Shaft Impact crusher at CEMCO’s facilities in Belen, NM, was shipped to EPS laboratory in Kentucky for metallurgical testing. The material consisted of leached oxide and partially refractory material with an average silver head grade of 48.12 g/t, which was considered depleted by Kinross when mining and processing ceased in 1998.

A representative portion of the bulk sample was weighed and sieved to separate two fractions. Material smaller than 2 millimeters was used for testing. The tests were conducted on 1 to 2 kg splits of the sieved (<2 mm) material. Splits tested were prepared according to acceptable industry standard practices (homogenized, coned and quartered several times). The minus 2 mm size was selected because of economic reasons, as it is a size fraction that can be achieved with one single stage of HPGR crushing. This is inexpensive relative to milling and yields better silver recoveries than those obtained by leaching the coarser (1 inch = 25.4 mm) material existing in Candelaria’s leach pads.

The current silver recoveries using EPS’ proprietary solutions average 49% on samples as received at the lab (<2 mm = 2000 microns), which significantly exceed the 20.9% and 29% silver recoveries achieved with cyanide leaching from bottle roll tests using material of similar size respectively (See the Company’s news release dated May 21, 2019).

Further milling for short periods (5 to 13 minutes) yields finer material (550 to 110 microns = 0.55 to 0.11 mm), increasing silver recoveries to between 59.9% to 64.4% (see details in Table 1). These recoveries far exceed the silver recoveries by traditional cyanide leach methods. Historic cyanide heap-leach silver recoveries of fresh ore, as reported by Kinross and its predecessors, averaged 51% during the open-pit life of the mine in the 1980’s and 90’s. Subsequent testing by Silver One using cyanide on partially leached material yielded recoveries in the 21-29% range for LP1 (see Company’s news releases of April 19, 2018 and May 21, 2019). All EPS’ tests had a leach time of 24 hours (non-optimized, EPS estimates that leach times can be reduced with additional testing) indicating that the historic long leach times of days or months have the potential to also be reduced significantly. For comparison, earlier bottle roll tests conducted by the Company on leach pad and fresh mineralization samples have been run for 46 to 96 hours and column tests for 120 days (See the Company’s news releases dated May 21, 2019 and December 13, 2022).

Final results from Extrakt are anticipated in the latter part of 2024. These results will be used in an anticipated economic study on the Candelaria project.

Analytical and QA/QC

Samples were assayed both by the Advanced Materials Institute (AMI) Bowling Green, Ky, and by American Assay Laboratories (“AAL”) in Sparks, NV, USA., (IAS accredited Laboratory, ISO/IEC 17025:2005). AMI and AAL insert blanks, standards and include duplicate analyses to ensure proper sample preparation and equipment calibration. AAL analyzed heads, tails and pregnant solution samples for gold and silver by ICP-Ultra Trace (ICP-AES+ICP-MS analyses) while AMI analyzed same samples for silver only by ICP-OES. Solids were digested in acid (hydrofluoric, hydrochloric and nitric acid) using teflon beakers. AMI and AAL are independent of Silver One.

Qualified Person

The technical content of this news release has been reviewed and approved by Robert M. Cann, P. Geo, a Qualified Person as defined by National Instrument 43-101 and an independent consultant to the Company.

About Silver One

Silver One is focused on the exploration and development of quality silver projects. The Company owns a 100%-interest in its flagship project, the past-producing Candelaria Mine located in Nevada. Potential reprocessing of silver from the historic leach pads at Candelaria provides an opportunity for possible near-term production. Additional opportunities lie in unmined historic resources as well as in previously identified high-grade silver intercepts down-dip, which can potentially increase the substantive silver mineralization along-strike from the two past-producing open pits.

The Company owns 636 lode claims and five patented claims on its Cherokee project located in Lincoln County, Nevada, host to multiple silver-copper-gold vein systems, traced to date for over 11 km along-strike.

Silver One also owns a 100% interest in the Silver Phoenix Project. The Silver Phoenix Project is a very high-grade native silver prospect, recently permitted for drilling, which lies within the “Arizona Silver Belt,” immediately adjacent to the prolific copper producing area of Globe, Arizona.

About Extrakt

Extrakt Process Solutions is a technology company that is focused on separation technologies for recovering precious metals, hydrocarbon separation as well as dewatering of mine waste and other related processes. The company has a global patent portfolio and continues to develop new processes and technologies.

See www.extraktps.com

For more information, please contact:

Silver One Resources Inc.

Gary Lindsey – VP, Investor Relations

Phone: 604-974–5274

Mobile : (720) 273-6224

Email : gary@strata-star.com

Forward-Looking Statements

Information set forth in this news release contains forward-looking statements that are based on assumptions as of the date of this news release. These statements reflect management’s current estimates, beliefs, intentions and expectations. They are not guarantees of future performance. Silver One cautions that all forward-looking statements are inherently uncertain, and that actual performance may be affected by a number of material factors, many of which are beyond Silver One’s control. Such factors include, among other

things: risks and uncertainties relating to Silver One’s limited operating history, ability to obtain sufficient financing to carry out its exploration and development objectives on the Candelaria Project, obtaining the necessary permits to carry out its activities and the need to comply with environmental and governmental regulations. Accordingly, actual and future events, conditions and results may differ materially from the estimates, beliefs, intentions and expectations expressed or implied in the forward-looking information. Except as required under applicable securities legislation, Silver One undertakes no obligation to publicly update or revise forward-looking information.

NEITHER TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS RELEASE.

Photo 1: https://mma.prnewswire.com/media/2376892/Leaching_results_NR_20240402.jpg

Photo 2: https://mma.prnewswire.com/media/2376893/Candelaria_map_with_Leach_pad_location.jpg

Logo: https://mma.prnewswire.com/media/1574720/Silver_One_Logo.jpg

View original content to download multimedia:https://www.prnewswire.com/news-releases/silver-one-reports-on-metallurgical-test-results-using-innovative-separation-and-leaching-technology-at-its-candelaria-silver-mine-nevada-302105123.html

SOURCE Silver One Resources Inc.

View original content to download multimedia: http://www.newswire.ca/en/releases/archive/April2024/02/c6517.html